|

This story goes back a couple of years when our Truma then just over a year old started dripping from the condensate tube. Its something that is not supposed to happen but after consultation with Dometic they declined to repair it under warranty. It was just a small leak after all and for a while I just let it drip to the ground until it became an embarrassment then I drilled out the plastic vent cover and fitted a tube to it to discretely let it fill a bucket. This was fine for around 2 years but after our last summer in South Australia the flow rate started to increase from a drip every few seconds to 5 drips a second or more and with the dropping temperatures with winter coming on a lot of hot water was getting wasted. You may ask why I didn't just get a new one, well truth is I did consider it until a fellow Boroma owner on his second one sprung a leak just short of 12 months and was just in time to get Dometic to cover his replacement tank. This galvanised my determination not to line Dometic's pockets for another one of theirs that may only last us 12 months. I did lots of research of all types of domestic gas and electric HWS but in the end it became obvious that the only real choice was between the two other RV hot water systems on the market. Suburban model SW6DEA won in the end because they seem to have avoided bad press generally on forums with the biggest complaint being stinky water as a result of the action of the sacrificial anode doing its job. We had a Suburban previously in our motorhome and when we sold it at 8 years old it was still going strong and I know it was still working a year later. It was a crude light the gas with a match system but it did the job. Our new Suburban is both gas and electric and is all operated from the inside so it a real step up from that old one and in line with the convenience of the Truma without the trauma !! I was able to source one on eBay from a caravan dealer for $889 including courier delivery. This installation was done on our three and half year old Boroma but the basic concept would cover other vans. If you feel uncomfortable connecting the electricity or gas please use a qualified tradesman to do that for you or have a caravan place do the whole job, its not for everyone. |

|

|

| This is what I started with, you need to remove all the service connections, sink drain, hot and cold pipes from both the HWS the sink and the water filter, 240v & 12v power connections and lastly the gas. This is necessary as the Truma is withdrawn from inside. | The outside, firstly discard the dust cover then remove the 4 self tappers that hold on the plastic vent. |

|

|

| The sealant will most probably have glued on the plastic vent so slide a blade under the edges to release it. The plastic on mine managed to disintegrate when trying to lever it off but its going to the tip anyway. | Undo the four hex bolts that hold in the aluminium part onto the internal bits. |

|

|

| Now you can use as much force as necessary to remove the aluminium panel. | Next you need to start removing those service connections. make sure the water is off, the 240v and 12v have their circuit breakers tripped and the gas needs to be off at the bottle. There should be a water ballcock and gas tap under the shelf or at least nearby. They should be off also. |

|

|

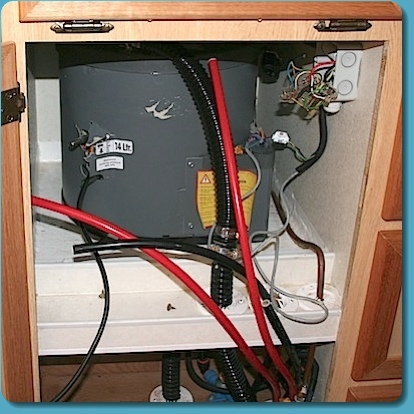

| This junction box is where the 240v for the HWS is connected. I decided to reuse the already installed 240v switch so the Suburban will be connected here. | The plumbing has been removed along with the water filter and all needs to be pulled back below the shelf to remove the old tank. |

|

|

| There are potentially 3 of these hold down brackets screwed down to the shelf/floor. Mine had only a single self tapper holding it down. | Once you shuffle the tank out of the way you can disconnect the gas connection using a suitable spanner. This connection was particularly tight and the pipe needs to be cut to remove the threaded connections from the pipe. The suburban needs a longer pipe so no need to save the existing one. |

|

|

| Most of the plumbing remaining here needs to be removed and discarded and the holes thru the floor sealed. | The tank can now be removed leaving an empty cupboard. I marked out the cut out width inside the cupboard then drilled a hole at the two bottom corners about 1cm from the base. On the outside I measured down from those holes and drilled back into the cupboard from outside. This should put you right at the floor level where the suburban will be fitted. Mark out a 325mm square on the outside ready to cut it out. You will see that the old cutout is off to one side as the Truma vent is made that way. Note the reflector has been removed from below the HWS and will be repositioned and the holes sealed after installation is finished. |

|

|

| NOTE:- THIS IS REALLY IMPORTANT. There may be wiring concealed in the wall so you need to first cut the fibreglass without cutting any deeper to avoid disaster. I used a diamond tipped blade in the angle grinder but a cutoff wheel would do just as good but don't be tempted to use a jigsaw !! | Next I made several cuts to enable me to pry off the fibreglass skin and expose the framing (and the hidden wiring) |

|

|

| Pry out the insulation just to be sure of what's underneath. You can see one mains wire crossing the cutout but there is another hidden just above it. At the bottom is 12v wiring for the clearance lamp below. | Once I had located all the danger areas I cut the frame and inner wall skin out with a jigsaw being careful to keep clear of any wires. The outer trim frame was inserted and the mounting holes drilled so as to ascertain where to put the frame around the hole and what bits of wall frame needed to be removed first to allow it to be fitted and the wires safely stowed. |

|

|

| After fitting the 20x20mm meranti frame in the wall surrounding using liquid nails I glued and sealed it to the fibreglass filling all the gaps and coating the wood with a skin of Sikaflex marine sealant. Also at this time the tank was inserted to check that it was a neat fit and also to mark the position of the two 50x50mm meranti blocks that Suburban recommend to hold the tank. These were chamfered at 45 degrees so as to sit firmly against the foam insulation before gluing and screwing to the shelf. While this is drying you can connect up a 240v lead to the mains connection box on the top of the Surburban leaving the end free to connect up at the junction box later. | After the sealant has had time to dry then following the instructions from Suburban the outer frame is sealed to the inner control box and then a generous seal of Sikaflex to seal the whole thing to the wall. Note there are three screws that are used to hold the frame to the control box section. The Boroma having quite an undulating wall skin required packing out between the frame and the wall where the dips are. This was done with 5mmx10mm plastic strips shown below that is used to join flooring plywood but I leave the choice of packers to you. I used masking tape to protect the area around the frame and a plastic tool to give a neat 4mm curve to the Sikaflex. |

|

|

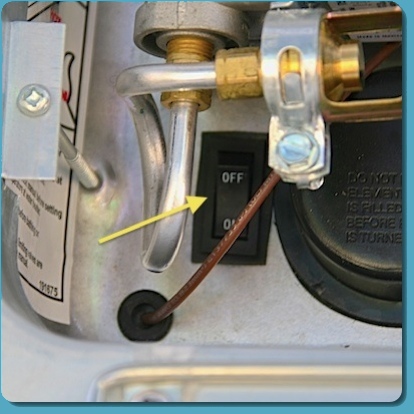

| Reconnect all the plumbing and connect the 240v back to the junction box. NOTE. There is a 240v switch on the outside of the HWS that is fitted with a pin to stop you connecting power before the tank is filled with water (see below), Remember This. Do not be tempted to change the plumbing and connect into the hot and cold to the sink the water from the HWS must be plumbed in some way back from any tap to prevent hot coming the cold tap. The original plumbing on mine is tee-ed in about a meter away. On the left hand side is the 12v control for the gas that I connected using the existing cable to the Truma gas switch but elected to fit the Suburban switch rather than bother modifying the Truma one. | NOTE both these pictures were taken after the job was finished but once you have water and power connected and there are no leaks you can make sure that it all works OK on 240v before continuing. The copper pipe is the gas line they needs to be bought from a gas fitter with the fittings added and the ends flared. |

|

|

| This is a shot of the two switches showing the old reused mains switch and the new suburban switch. I modified the switch plate to show a green LED when the gas is switched on and that is shown on the circuit below. There was insufficient cable at that end to put plugs on the wiring so I soldered them directly to the switch and the fault lamp connections. | Once you have connected up the 12v wiring and mounted the control box the last thing is to fit the gas line. This needs to be done up quite tightly to maintain a gas tight connection and checked with soapy water for leaks before igniting the burner. Once you have satisfied yourself that it is all working as expected on gas you need to seal the rubber grommet with silicon to prevent gas or fumes entering your van making sure to also seal the slit that is cut in the grommet. |

|

|

| This shows the plastic packing I used to cope with the fibreglass wall profile. | A copy of the 12v wiring circuit showing the connections for the LED indicator. |

|

|

|

The finished job showing the expansion valve fitted with a reducer to 6mm John Guest white tube and exiting via a conveniently placed grommet and thence thru the floor. This will keep any drips on the ground when the water expands as its heated. |

The location of the main 240V switch. |

|

|

| The optional John Guest non-return valve fitted in the cold feed to the HWS. This stops the hot water pressurising the cold when the tank is heating. I chose to fit it as I found the flush from the toilet was spraying over the lip because of the extra pressure but it may not have any effect in your setup. Note the direction of flow. |

All closed up and finished. Job Done

The Cost Suburban SW6DEA $889 Tube of Sikaflex marine $15 wood $5 900mm gas pipe $24 JG one way valve $24 JG 6mm tube & adapter $10 Total $967 |

|

I have added the following pictures for those who were wondering what a dead Truma looks like. The hole is tiny but over the time that it was leaking managed to lay down a fair quantity of disolved mineral along with rust. Strange for stainless steel I thought. |

|

|

| The stainless steel tank showing the mineral deposit and the location of the leak. | Close up of the leak. |

|

|

| The outer containment vessel showing where the spray of water had produced a rusty patch. | The tank with the rust removed to show the actual hole. I suspect that this is a tiny imperfection in the stainless steel. |

Send E-mail to

This information is for private use only and should not be misrepresented as your work or directly linked without the owners permission.